Aerospace Engineering

Precision & Performance

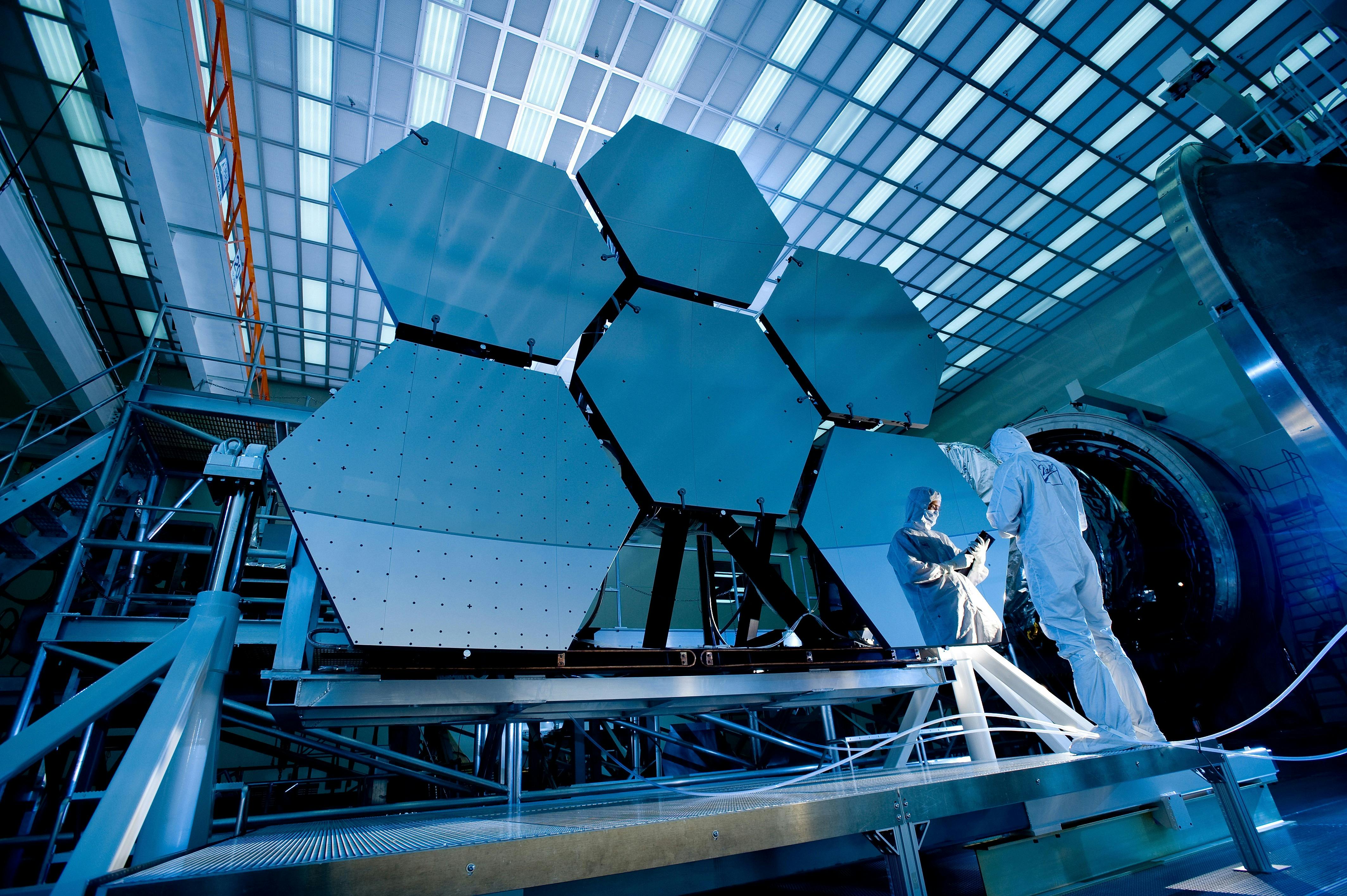

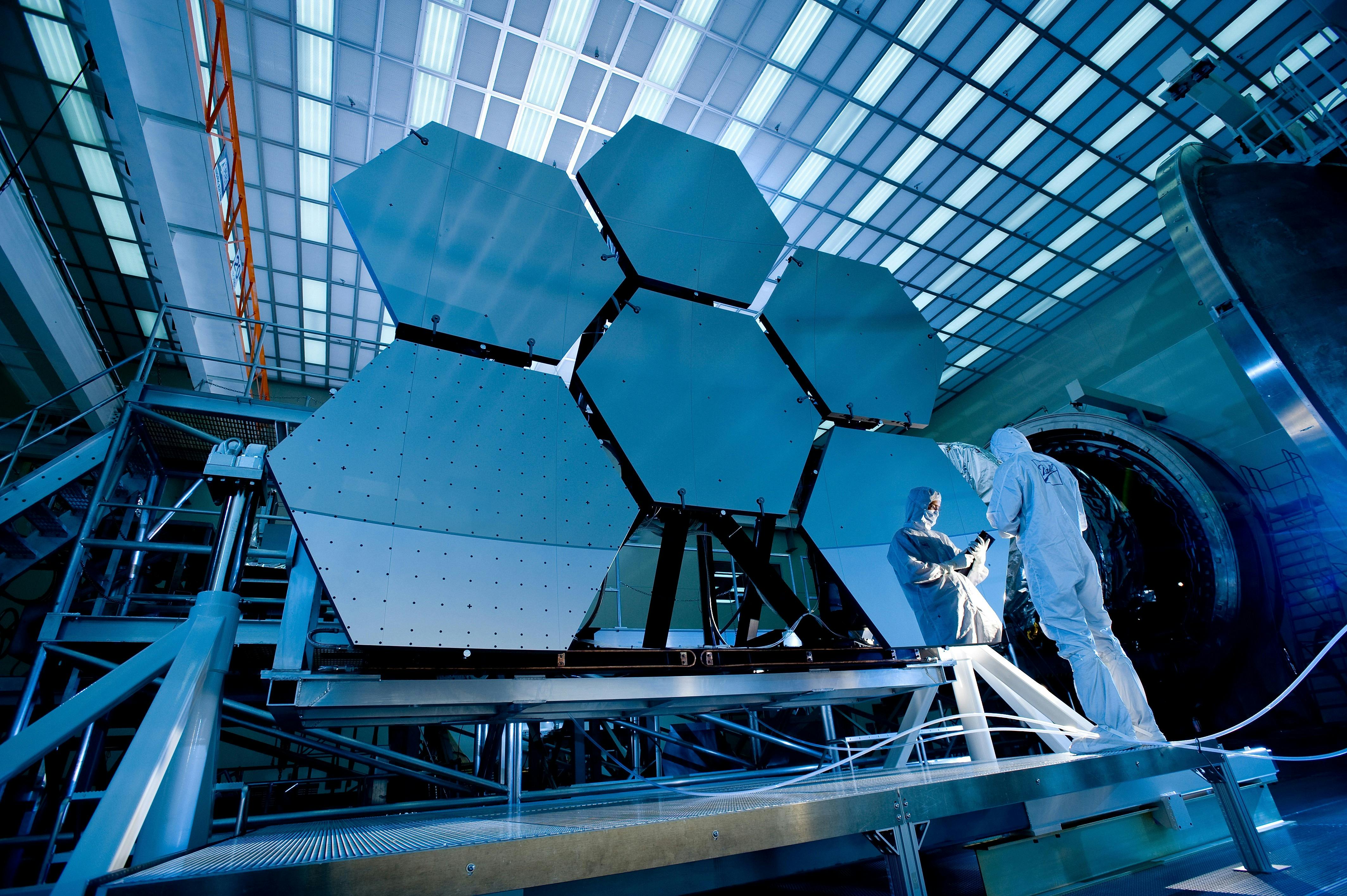

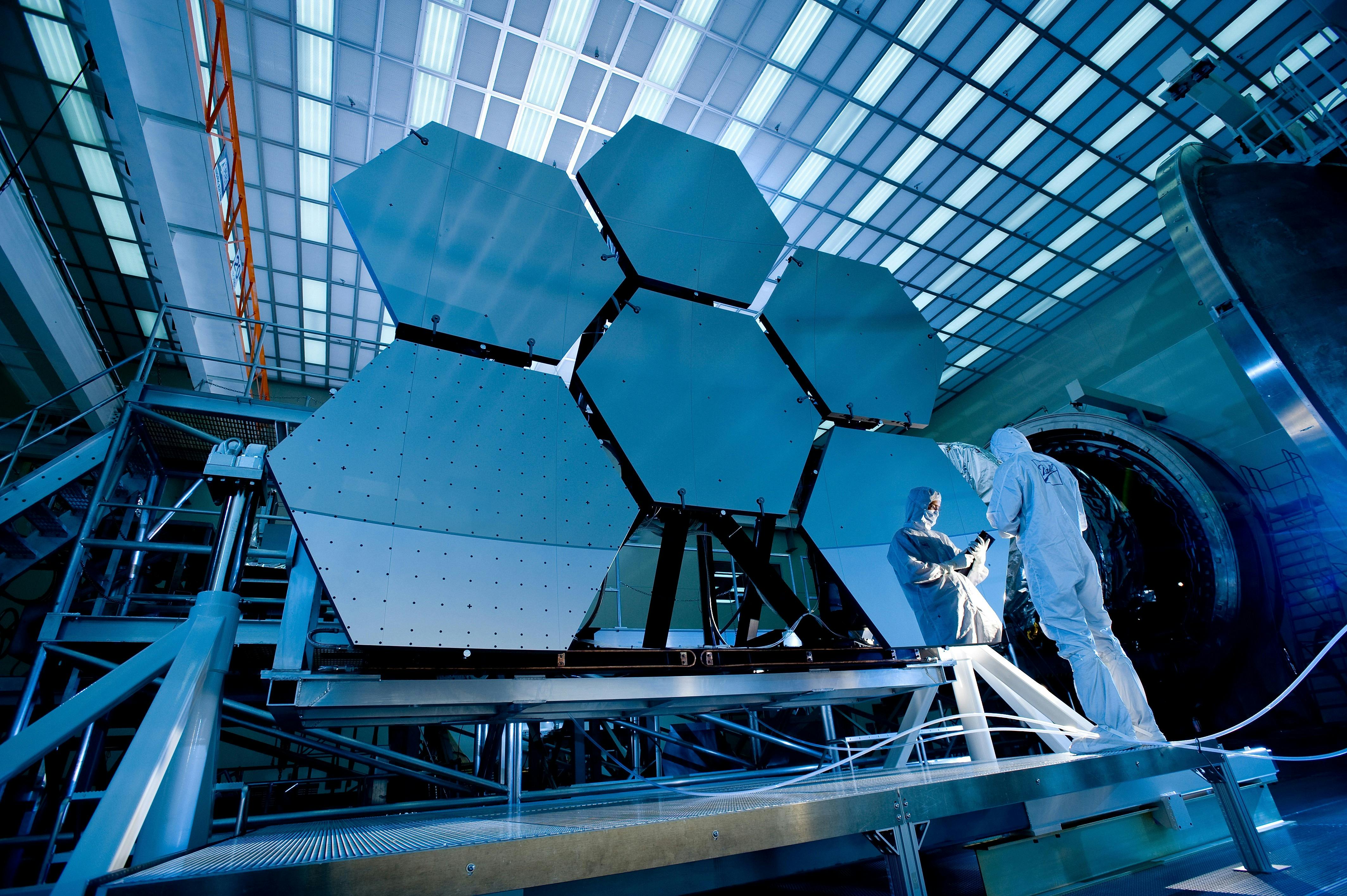

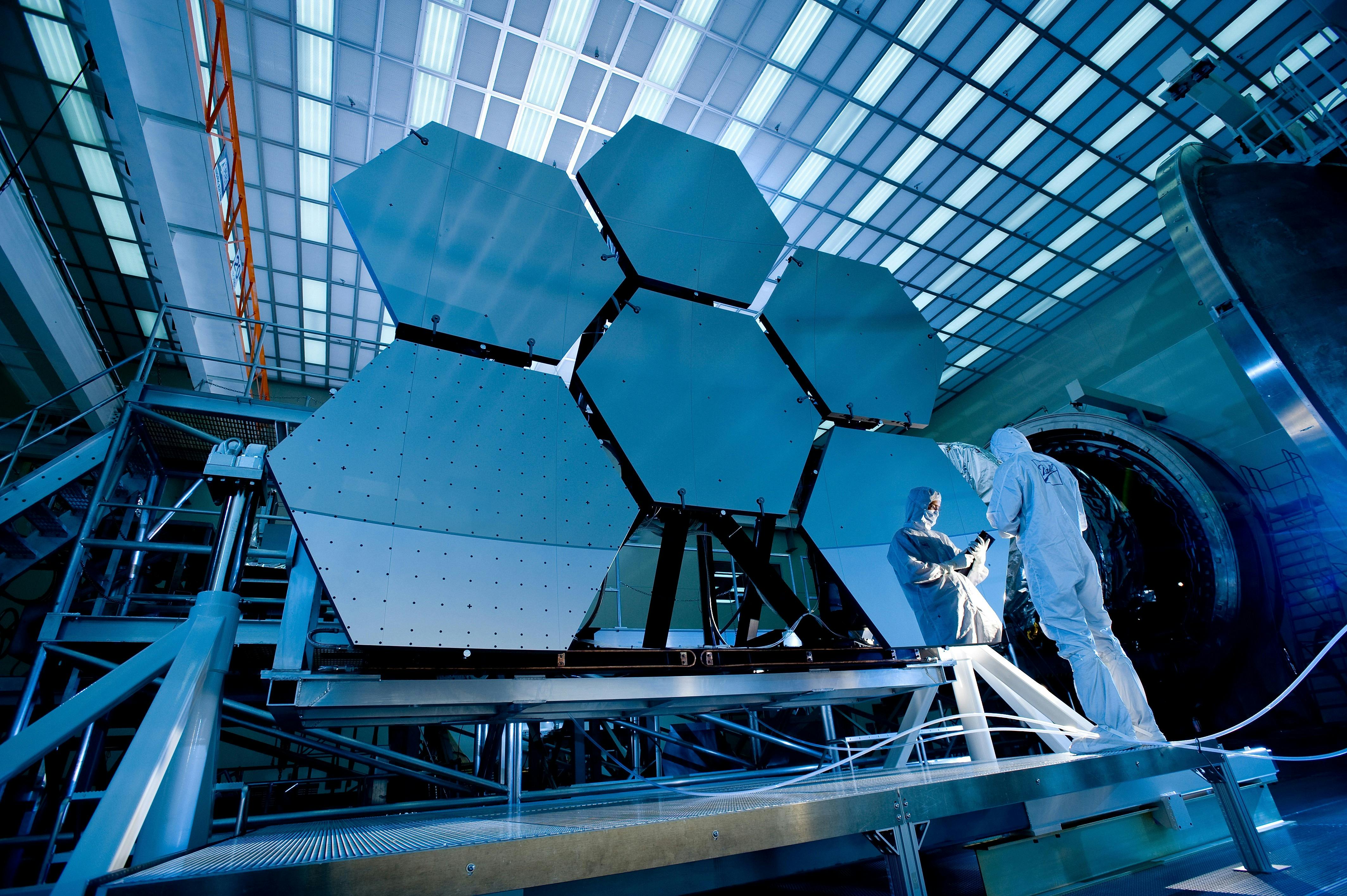

Aerospace is a highly specialized industry that focuses on the design, development, and manufacturing of aircraft, spacecraft, and related components. It is a field where precision, performance, and safety are of utmost importance. From commercial aviation to defense and space exploration, aerospace engineering plays a crucial role in advancing technology and human capabilities.

Our manufacturing processes are built to meet the highest industry standards, ensuring that every component we produce delivers reliable performance in critical flight operations. Precision engineering and advanced materials enable us to develop cutting-edge solutions for aircraft structures, propulsion systems, and avionics, contributing to the safety and efficiency of aerospace technology.

Utilizing state-of-the-art technology, our team designs and manufactures aerospace components that enhance efficiency, durability, and sustainability. We incorporate the latest advancements in aerodynamics, lightweight composites, and high-performance alloys to optimize aircraft functionality and fuel efficiency.

Every aerospace component undergoes rigorous testing and quality control before deployment. We adhere to strict regulatory compliance, ensuring that our products meet and exceed global aviation safety standards. Our commitment to excellence guarantees that each part performs flawlessly under extreme conditions.

From the development of next-generation aircraft to supporting space exploration missions, our expertise in aerospace manufacturing drives innovation. By combining precision engineering with cutting-edge technology, we contribute to the evolution of modern aviation and space travel, keeping aerospace at the forefront of technological advancement.

Medical Equipment Manufacturing

High-Precision Medical Tools

The medical equipment manufacturing industry plays a vital role in modern healthcare by designing and producing high-quality medical devices that enhance patient care and improve clinical outcomes. Precision, reliability, and safety are at the core of medical equipment manufacturing, ensuring that healthcare professionals can rely on advanced technology to diagnose, treat, and monitor patients effectively.

Our expertise in manufacturing medical equipment ensures that every component meets the highest industry standards. From diagnostic imaging systems to surgical instruments and life-support devices, we focus on delivering products that adhere to strict regulatory requirements and provide exceptional performance.

We utilize state-of-the-art technology, including CNC machining, additive manufacturing, and advanced materials, to produce durable and high-precision medical devices. Our manufacturing processes emphasize accuracy and consistency, ensuring that each product functions flawlessly in critical healthcare applications.

Quality assurance is a top priority in medical equipment manufacturing. We conduct rigorous testing and validation processes to ensure that every device meets global regulatory standards such as FDA, CE, and ISO certifications. Our commitment to compliance guarantees the safety and effectiveness of our products in real-world medical environments.

From surgical tools to patient monitoring systems, our solutions support healthcare providers in delivering optimal patient care. By integrating innovation and engineering excellence, we contribute to the advancement of medical technology, helping to improve lives and shape the future of healthcare.

Oil & Gas Industry Solutions

Advanced Drilling Technology

The oil and gas industry requires high-performance equipment and solutions that can withstand extreme conditions while maintaining operational efficiency. From exploration and drilling to refining and distribution, precision engineering and reliability are essential for ensuring safety and productivity in this critical sector.

Our expertise in manufacturing high-quality components for the oil and gas industry ensures that every part meets stringent industry standards. We specialize in producing durable and corrosion-resistant equipment used in offshore and onshore operations, pipelines, refineries, and petrochemical plants.

Utilizing advanced materials and cutting-edge manufacturing technologies, we develop solutions that enhance efficiency and longevity. Our products include precision-engineered valves, pumps, drilling components, and structural parts designed to operate in harsh environments, including high-pressure and high-temperature conditions.

Safety and compliance are at the core of our manufacturing process. We adhere to global industry regulations and conduct rigorous quality control testing to ensure that our components perform reliably under demanding conditions. Our solutions help minimize downtime, reduce maintenance costs, and optimize overall operational performance.

From upstream exploration to downstream processing, our oil and gas industry solutions support companies in achieving higher productivity and sustainability. By combining engineering excellence with industry-specific expertise, we contribute to the advancement of energy infrastructure and resource management worldwide.

Automotive

Automotive Solutions

The automotive industry is built on innovation, precision, and efficiency. As vehicles become more advanced, the demand for high-quality components and cutting-edge manufacturing processes continues to grow. From engine components to structural parts, every element must meet strict performance, safety, and durability standards to ensure optimal vehicle operation.

Our expertise in automotive manufacturing allows us to produce precision-engineered components that enhance vehicle performance, fuel efficiency, and safety. We specialize in developing high-strength, lightweight materials that contribute to modern automotive advancements, including electric vehicles (EVs), hybrid technology, and fuel-efficient combustion engines.

Using state-of-the-art manufacturing techniques such as CNC machining, robotic automation, and additive manufacturing, we ensure that every automotive component meets the highest industry standards. Our rigorous quality control processes guarantee reliability, minimizing defects and ensuring long-term durability.

Safety and compliance are at the core of our operations. We adhere to global automotive regulations and industry standards, ensuring that all our components contribute to vehicle safety, emissions control, and energy efficiency. Our continuous investment in research and development helps us stay at the forefront of automotive innovation.

From traditional internal combustion engine vehicles to next-generation electric and autonomous vehicles, our solutions support automakers in achieving higher performance, sustainability, and reliability. By combining engineering excellence with advanced manufacturing techniques, we help drive the future of mobility forward.

Automotive

Sheet Metal Solutions

Sheet metal fabrication plays a crucial role in various industries, including aerospace, automotive, medical, oil & gas, and industrial manufacturing. It involves cutting, bending, and assembling metal sheets into precise components that meet specific functional and structural requirements. With advancements in technology, sheet metal solutions have become more efficient, durable, and adaptable to complex designs.

Our expertise in sheet metal fabrication ensures high precision and quality in every component we produce. Using advanced techniques such as laser cutting, CNC punching, bending, and welding, we manufacture custom sheet metal parts that meet the highest industry standards. Our processes allow for tight tolerances, ensuring accuracy and consistency across all products.

We work with a wide range of materials, including stainless steel, aluminum, titanium, and other high-strength alloys, to create components that are lightweight, corrosion-resistant, and durable. These materials are carefully selected based on their application, whether for aerospace structures, automotive panels, medical equipment enclosures, or industrial machinery.

Quality control is a key aspect of our sheet metal fabrication process. Every component undergoes rigorous testing, inspection, and finishing treatments such as powder coating, anodizing, and plating to enhance durability and aesthetics. Our commitment to excellence ensures that our products perform reliably in demanding environments.

From small precision parts to large structural components, our sheet metal solutions support industries in achieving high-performance, cost-effective, and innovative manufacturing. By combining skilled craftsmanship with advanced technology, we deliver customized solutions that meet the evolving needs of modern engineering and production.

Automotive

Aero Assembly Solutions

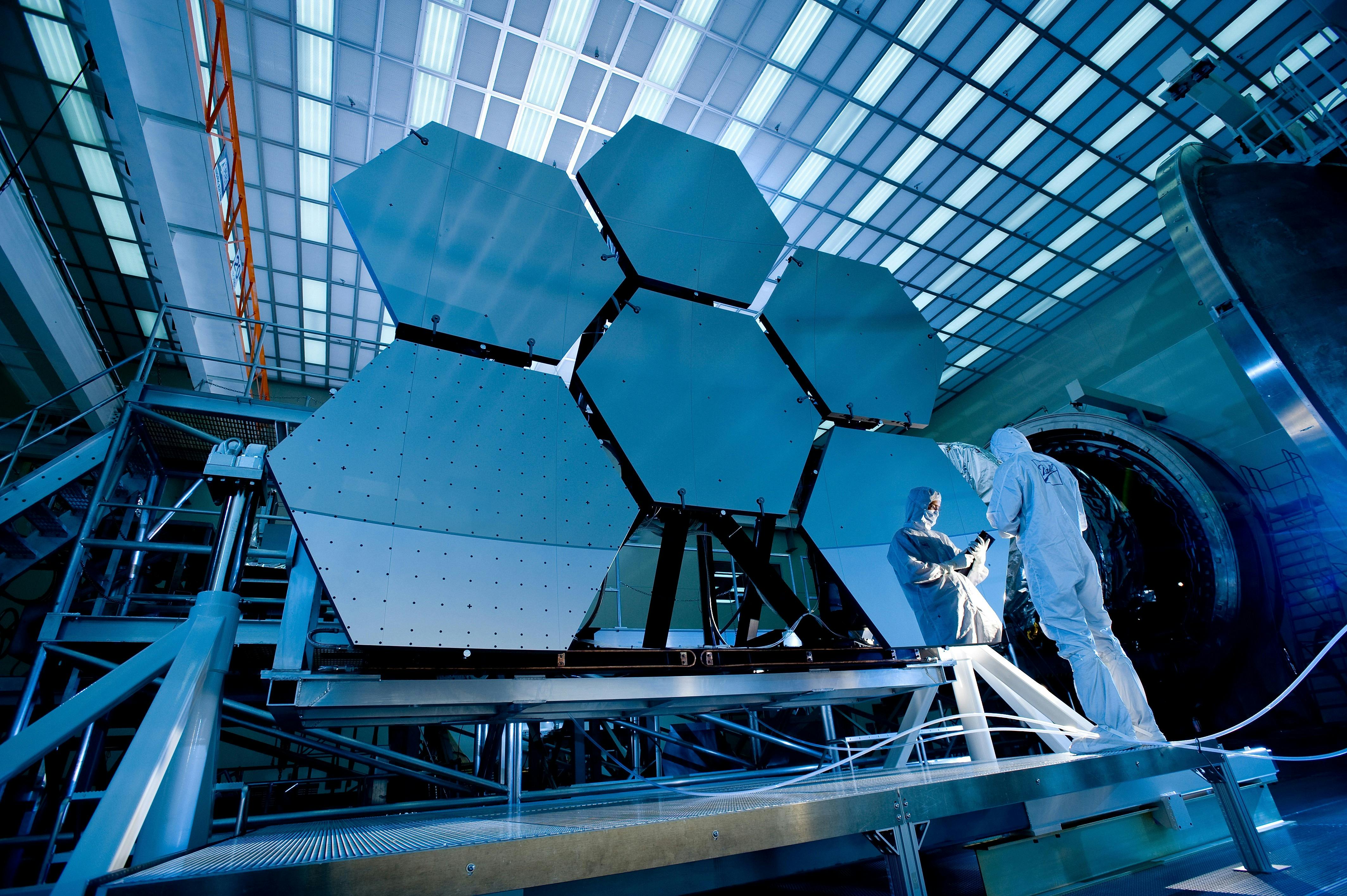

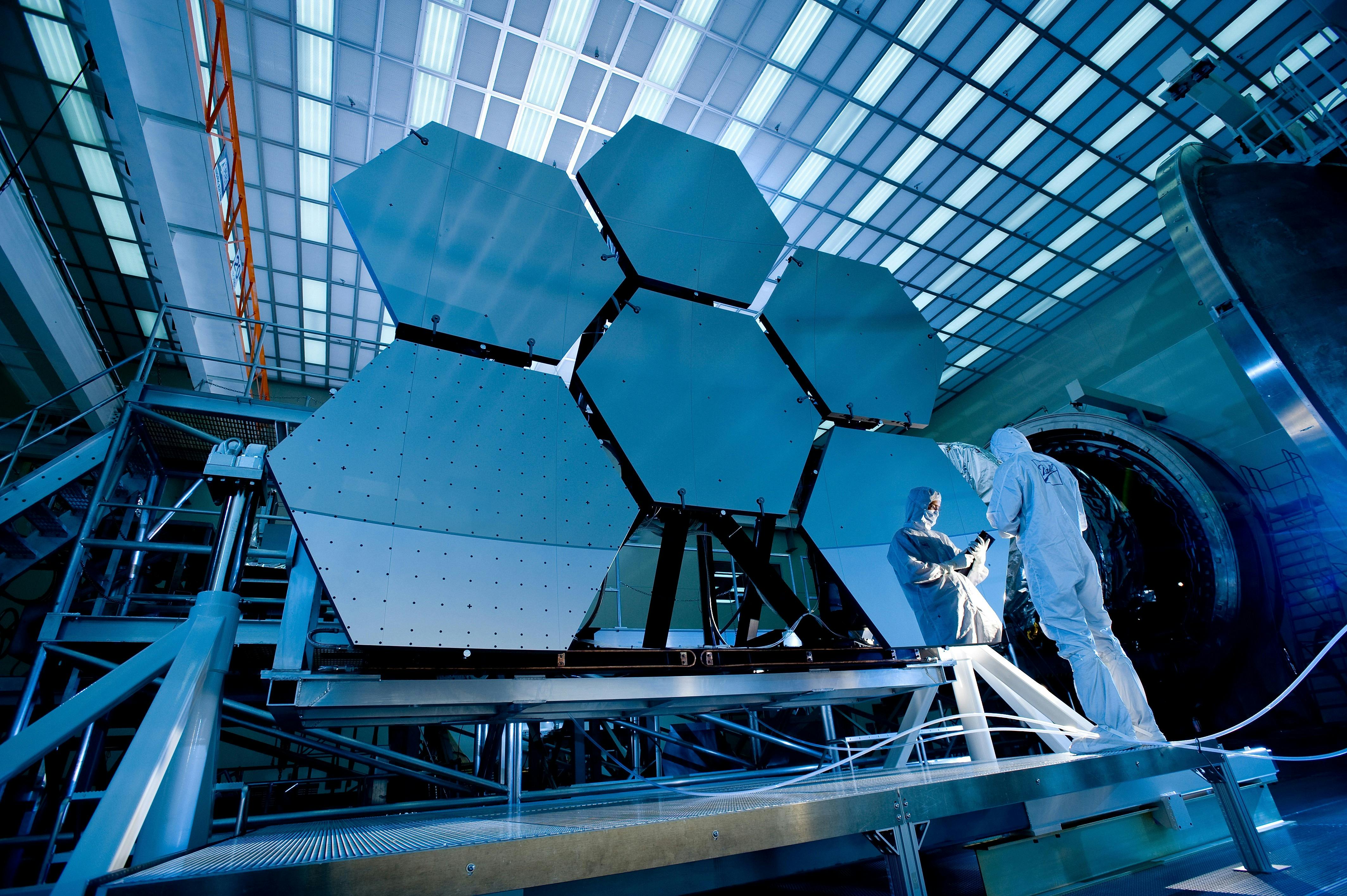

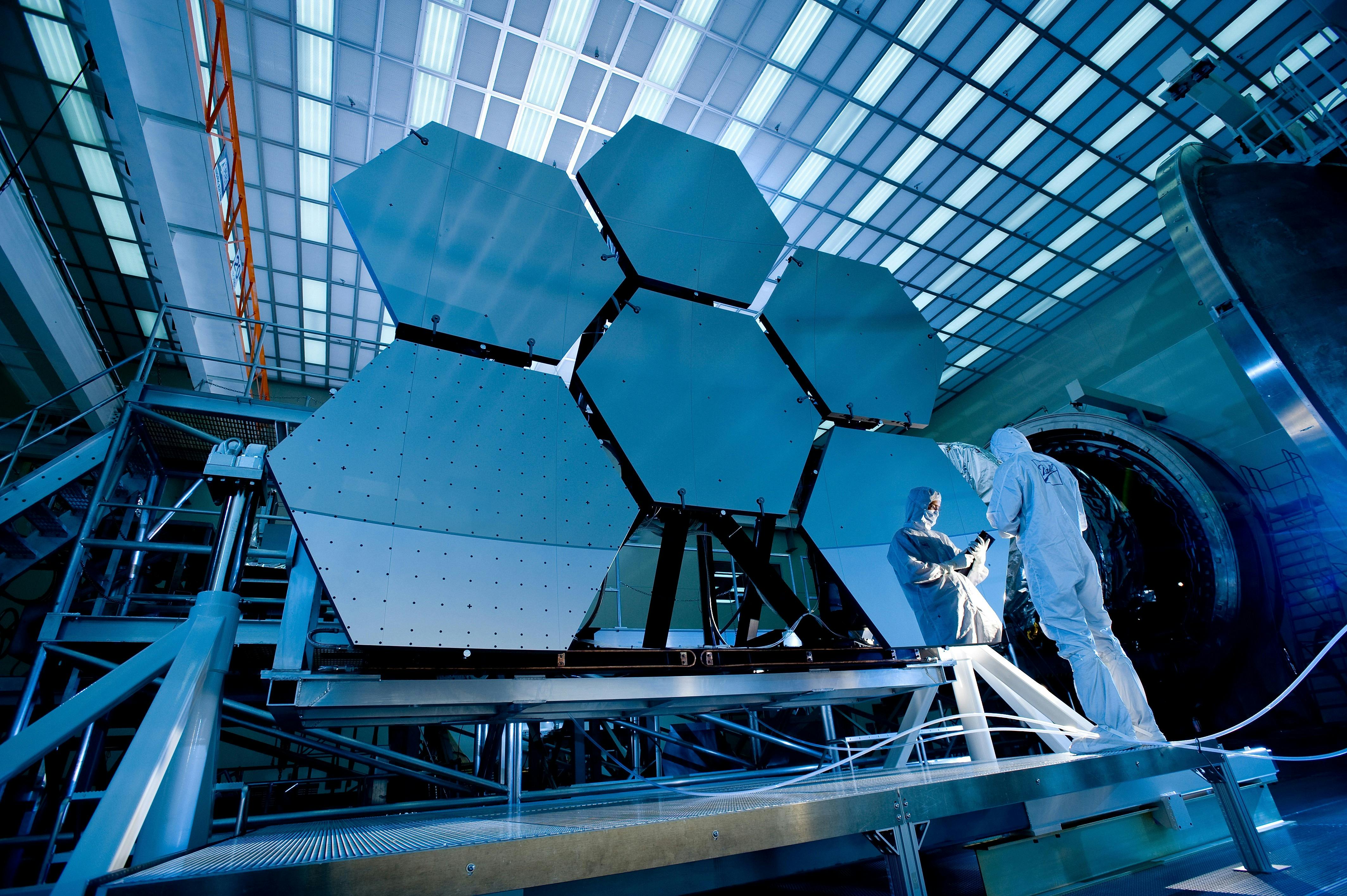

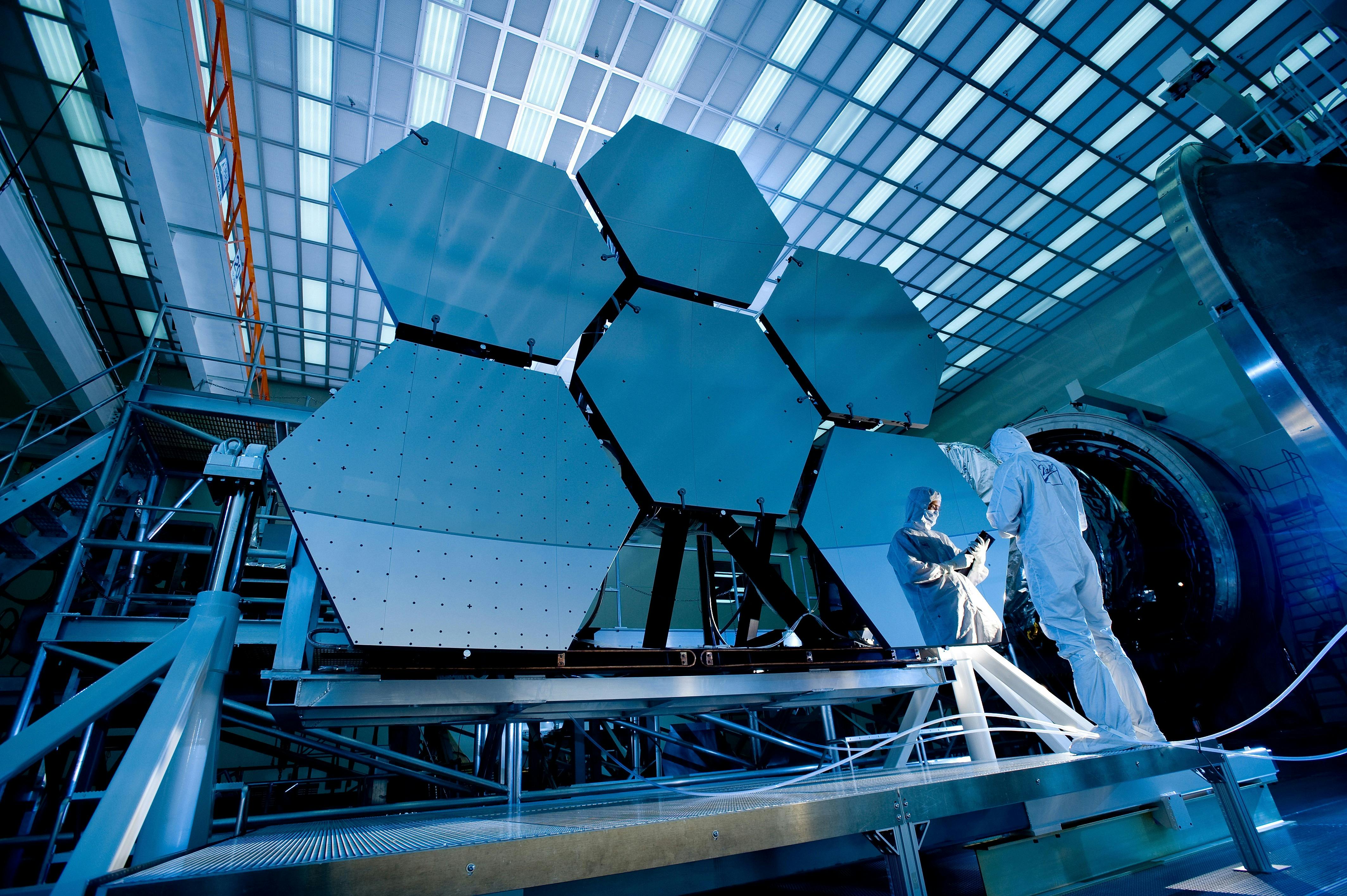

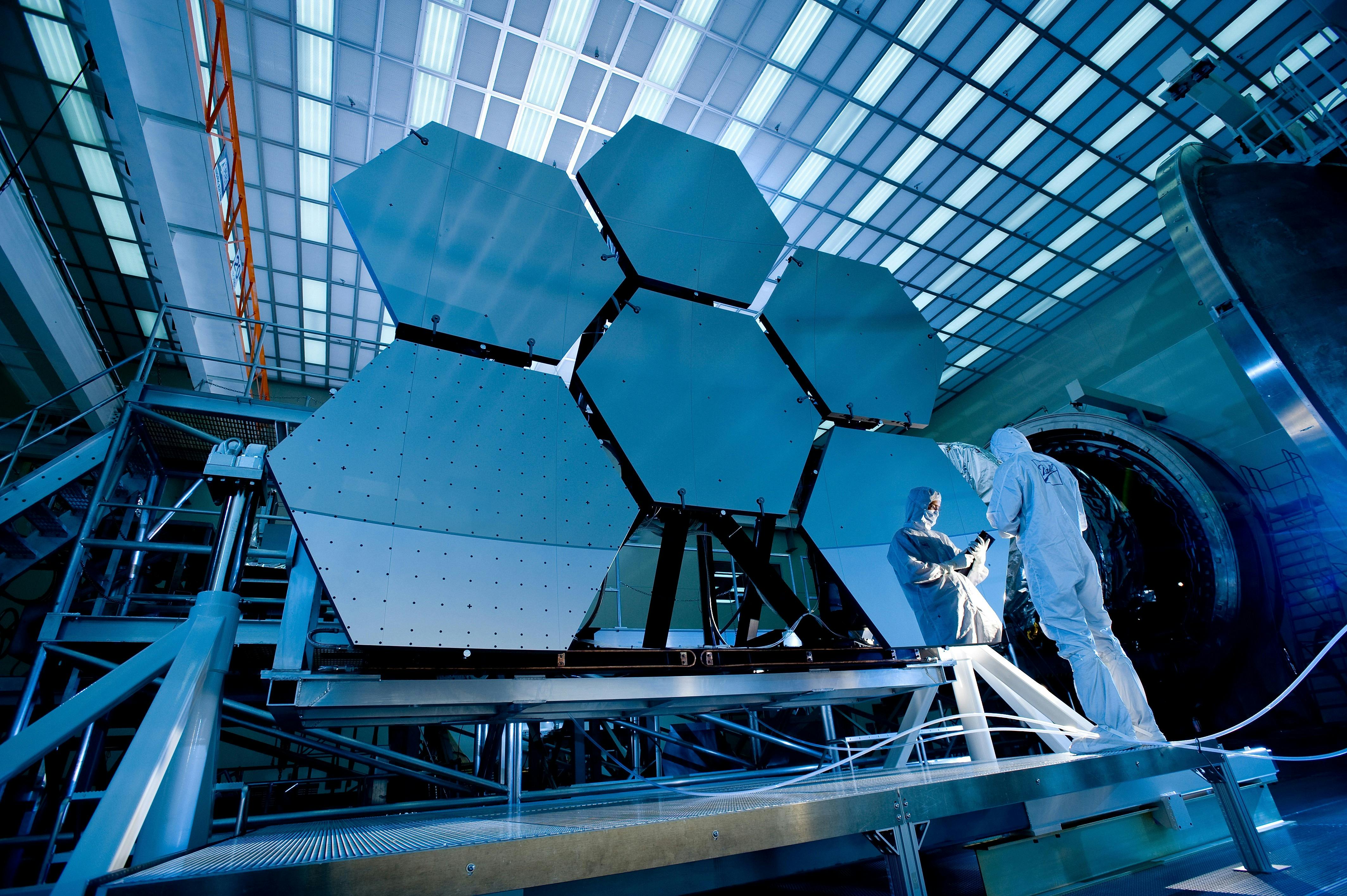

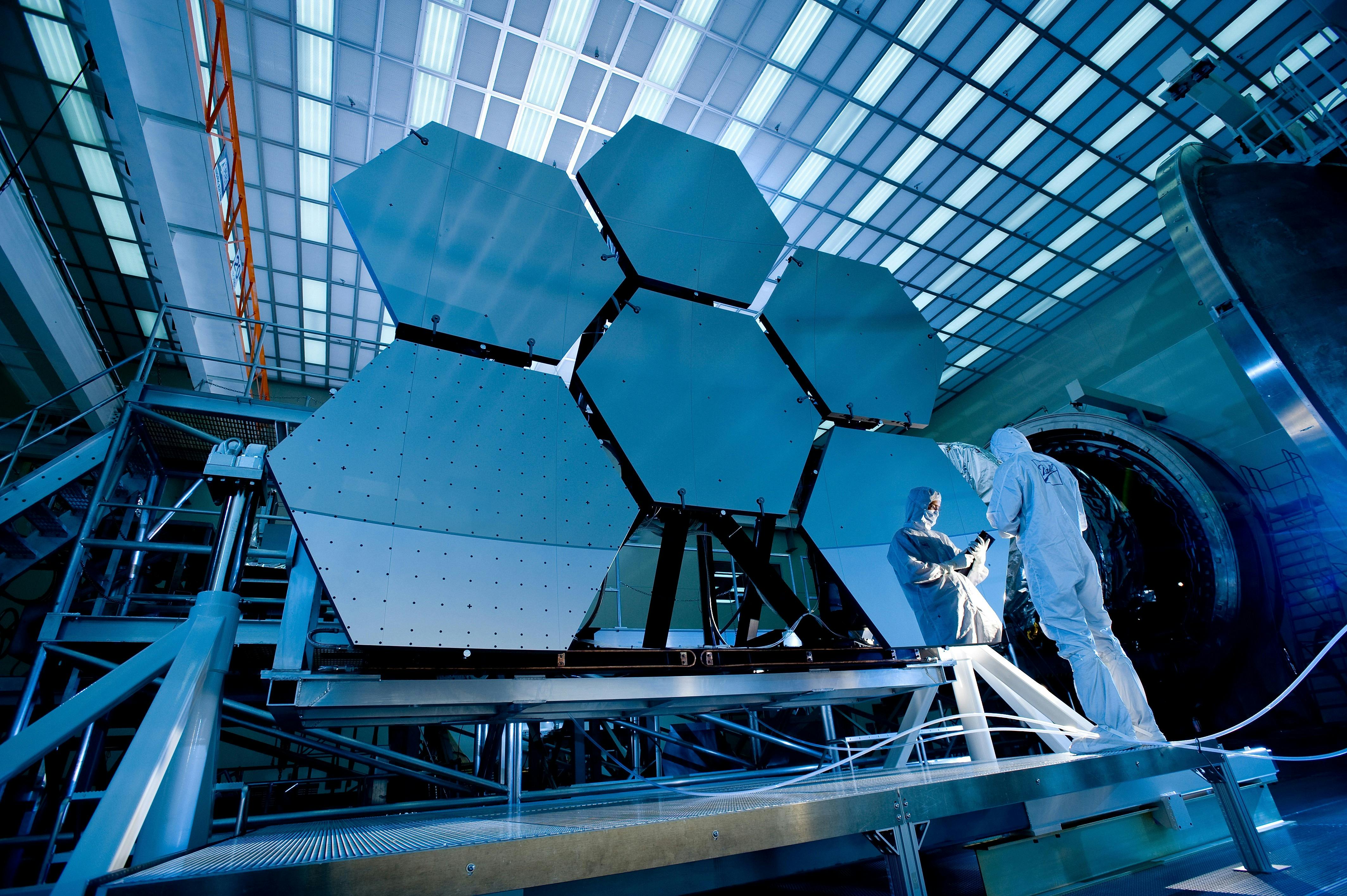

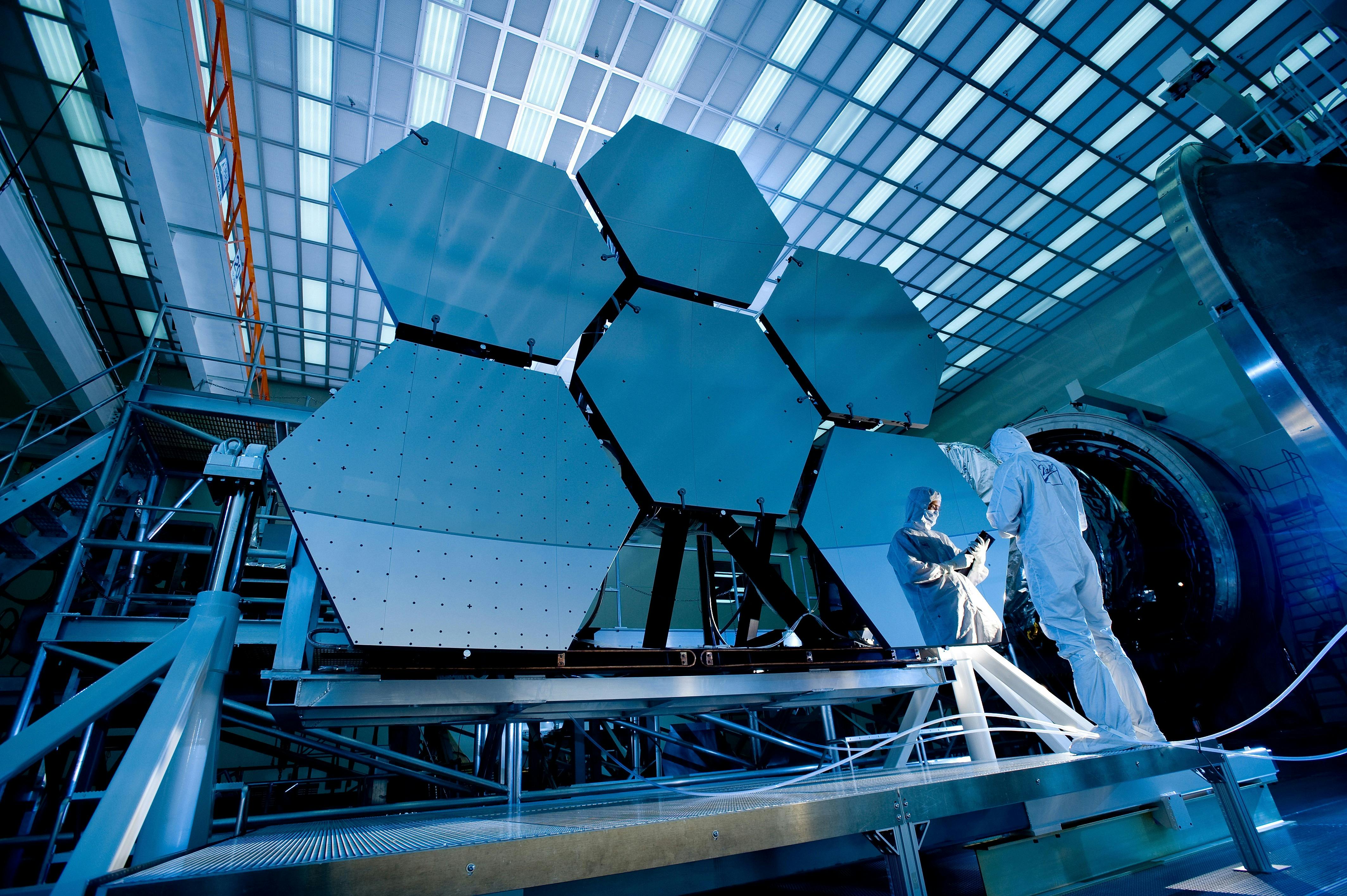

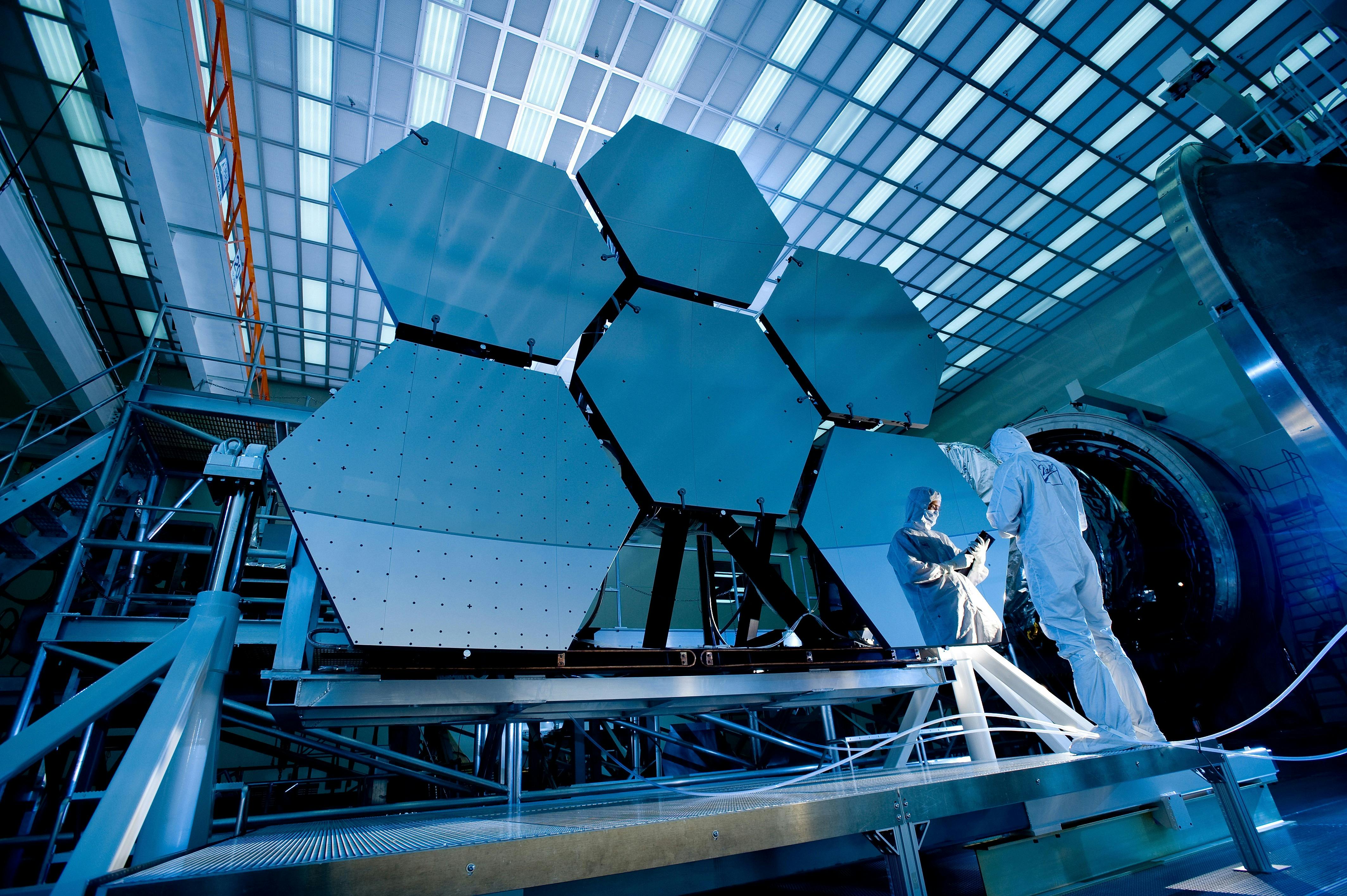

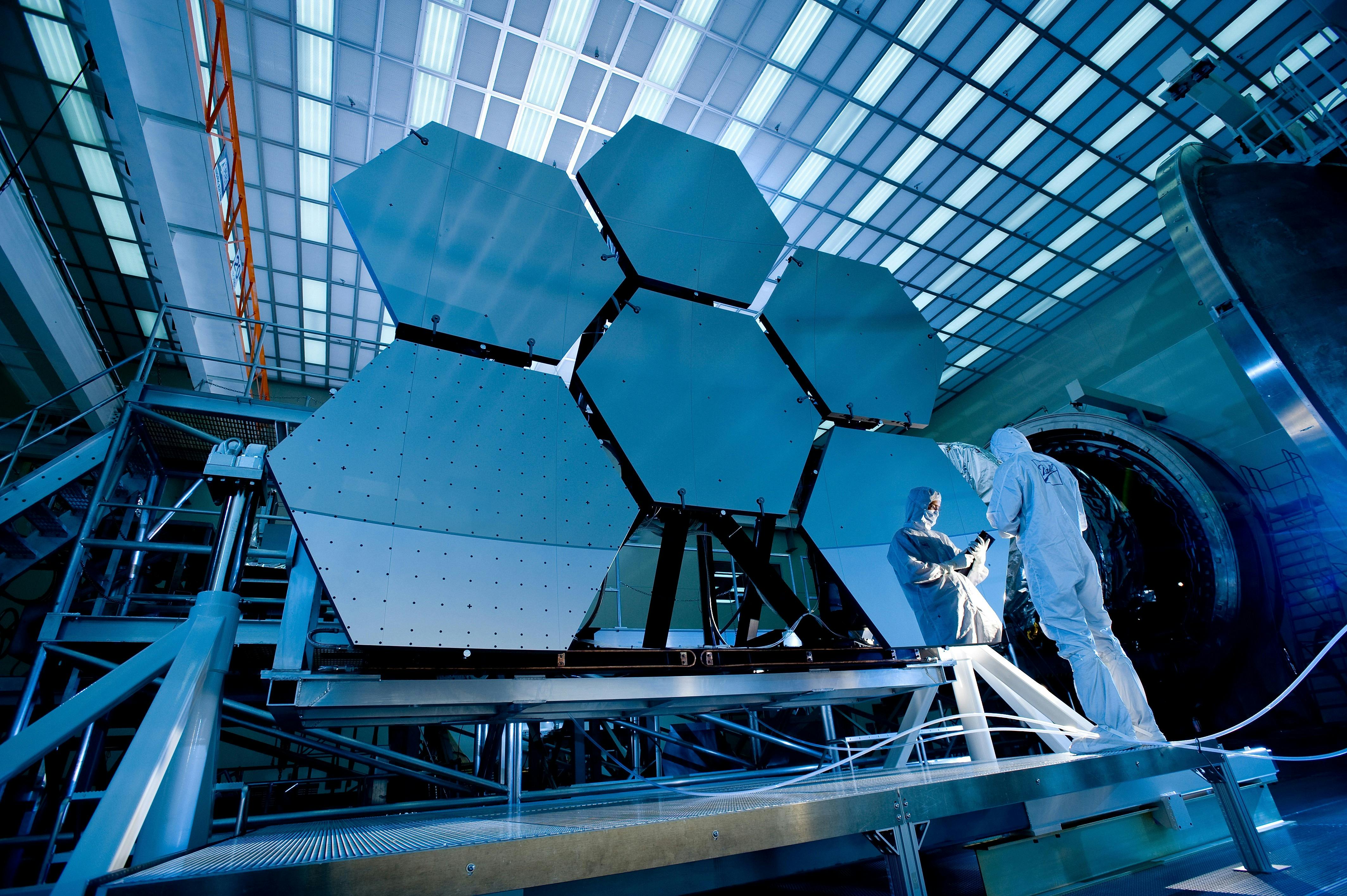

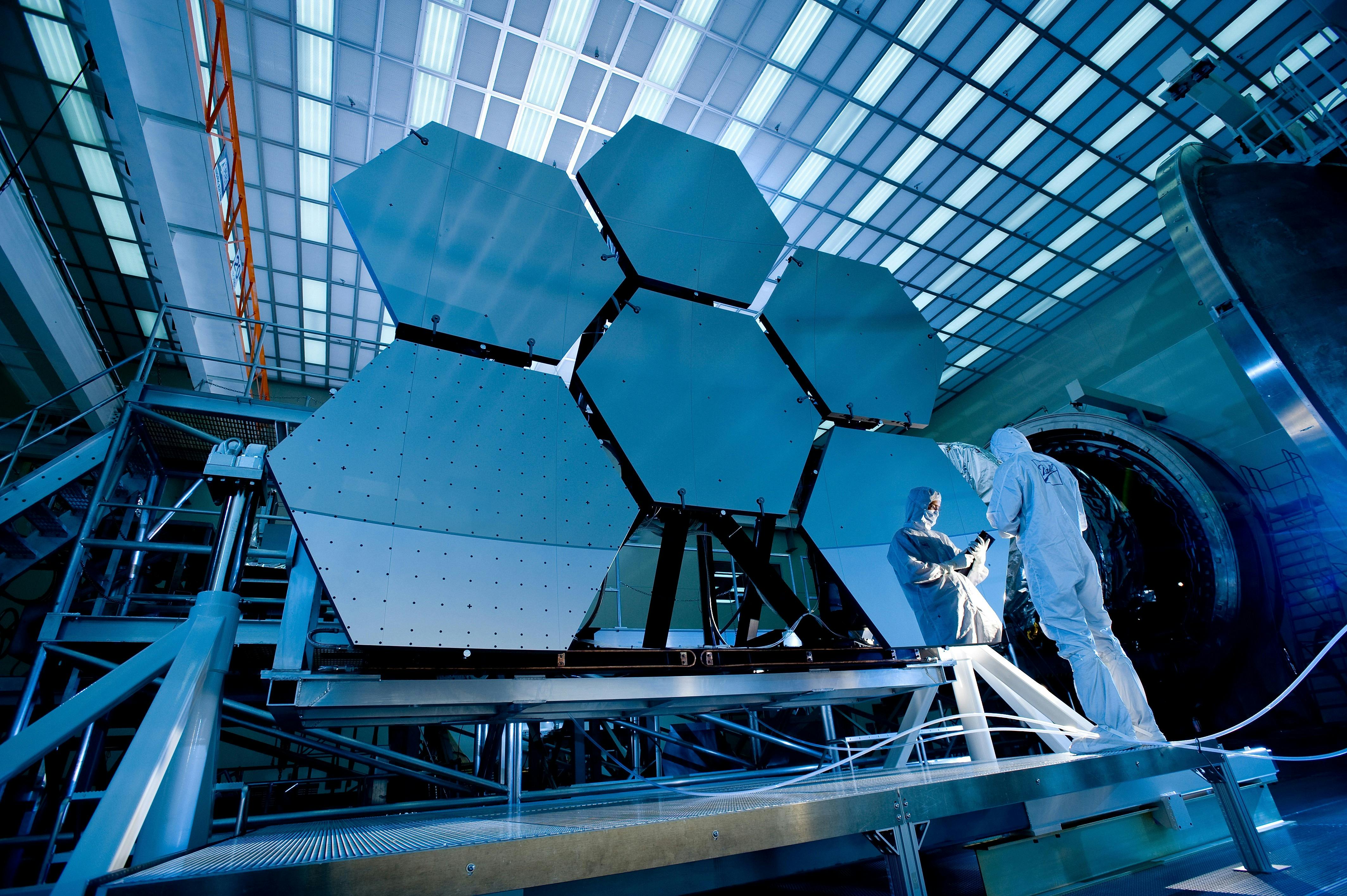

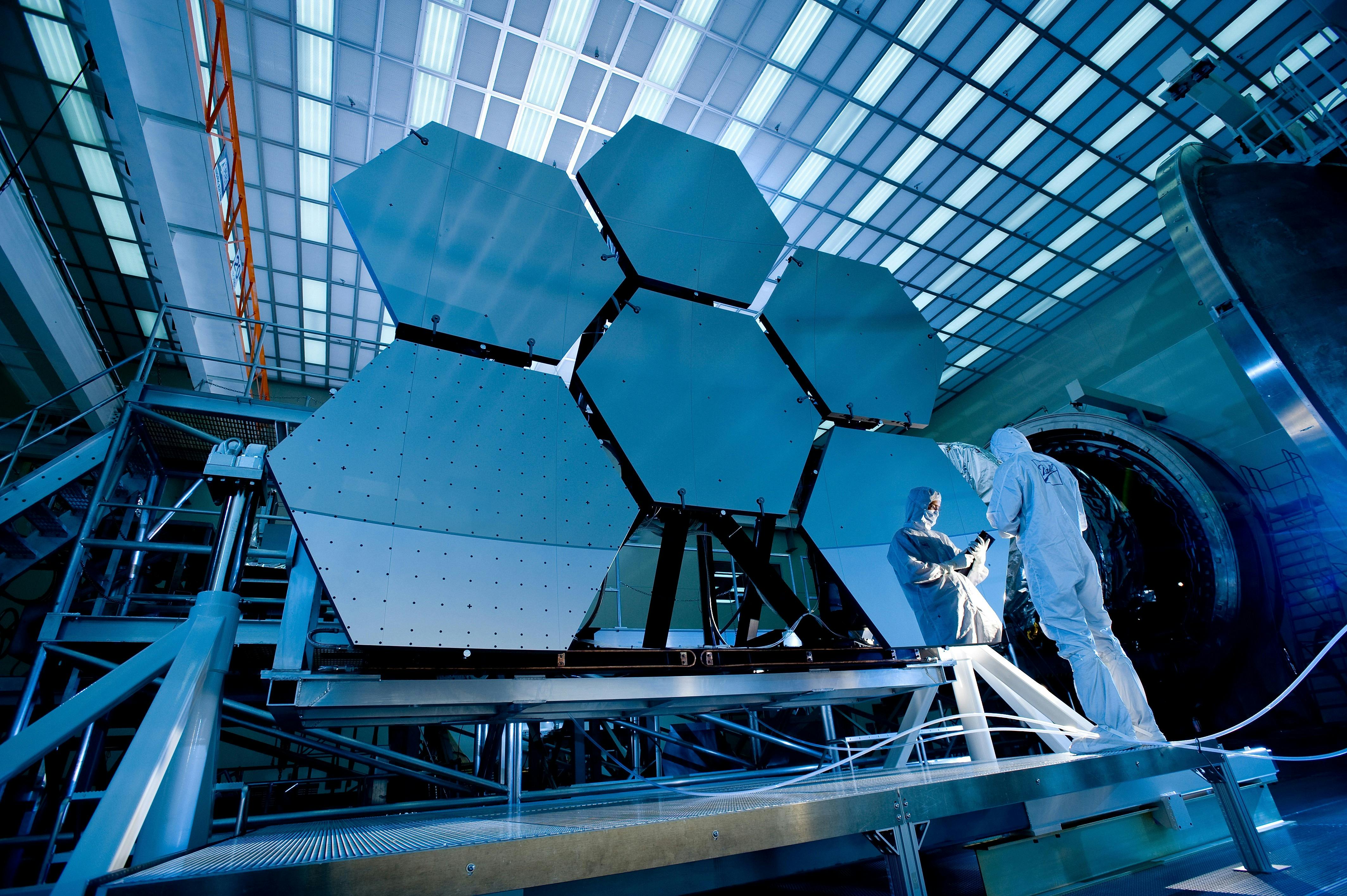

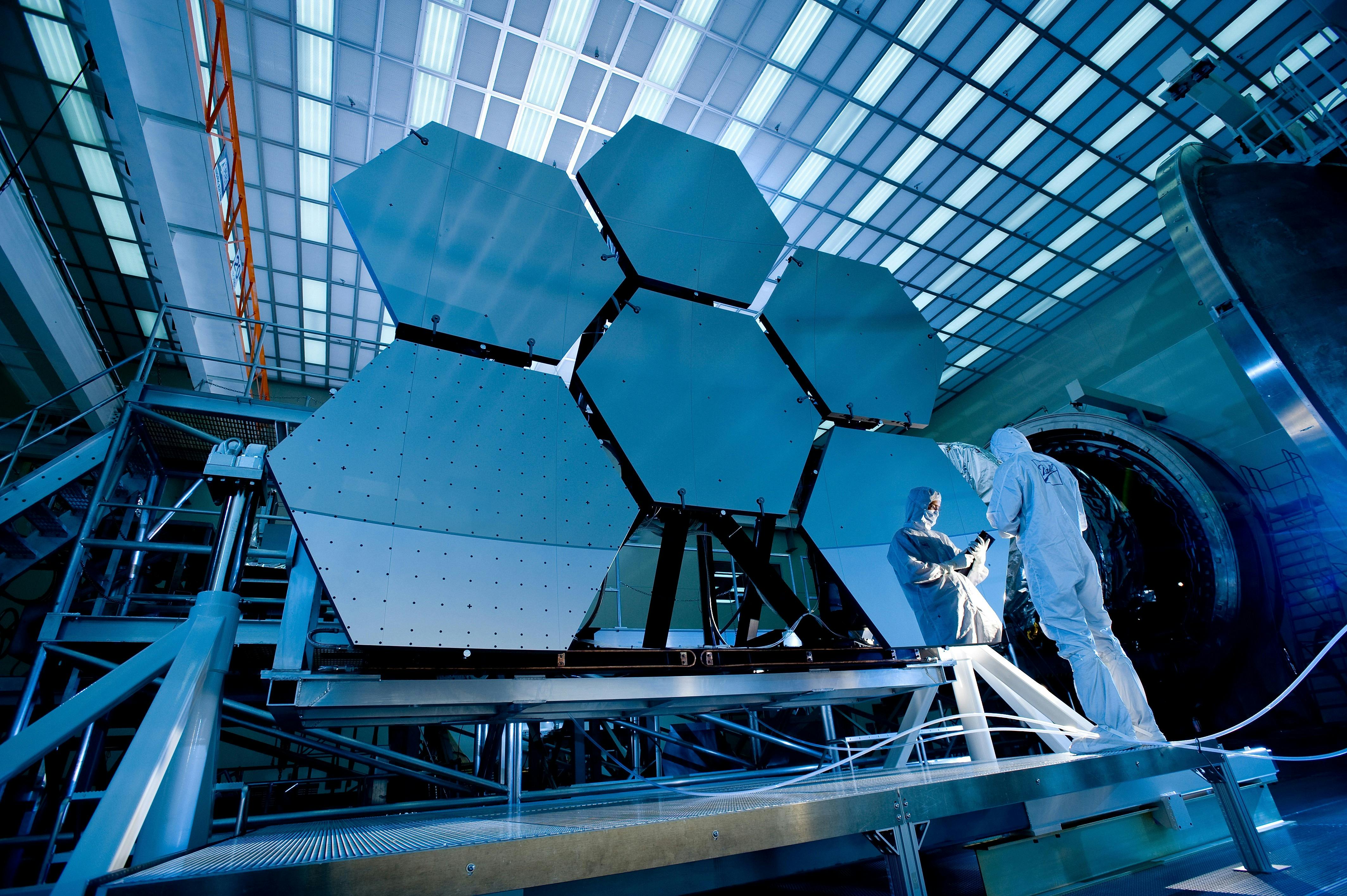

Aero assembly is a critical process in aerospace manufacturing, involving the integration of precision-engineered components to build aircraft structures, propulsion systems, and avionics. The complexity of aerospace assemblies demands high accuracy, strict quality control, and adherence to rigorous industry standards to ensure safety and performance in flight operations.

Our aero assembly solutions encompass the manufacturing and integration of essential aerospace components, including fuselage structures, wing assemblies, engine mounts, and landing gear systems. We utilize advanced assembly techniques, such as automated fastening, precision welding, and robotic integration, to ensure seamless component alignment and structural integrity.

With a strong focus on precision and reliability, we ensure that every aerospace assembly undergoes thorough inspection and testing, including non-destructive testing (NDT), pressure testing, and structural load assessments. These quality checks guarantee that all components meet global aviation standards, including AS9100 and ISO certifications.

Material selection is a crucial aspect of our aero assembly process. We work with high-strength alloys, composite materials, and lightweight metals to optimize aircraft performance, fuel efficiency, and durability. Our advanced assembly methods contribute to reducing overall aircraft weight while maintaining maximum strength and safety.

From commercial aircraft and military jets to space exploration vehicles, our aero assembly solutions support the development of cutting-edge aerospace technology. By integrating precision engineering with innovative assembly techniques, we help manufacturers achieve superior performance, efficiency, and compliance in modern aviation.

Water Jet

Water Jet Cutting Solutions

Water jet cutting is an advanced manufacturing process that uses a high-pressure stream of water, often mixed with abrasives, to cut through a wide range of materials with extreme precision. This technology is widely used across industries such as aerospace, automotive, medical, and industrial manufacturing due to its ability to produce clean, accurate, and burr-free cuts without generating heat or mechanical stress.

Our water jet cutting solutions offer exceptional versatility, allowing us to process materials such as stainless steel, aluminum, titanium, composites, plastics, and ceramics. Unlike traditional cutting methods, water jet technology does not create heat-affected zones (HAZ), preserving the structural integrity of the material and eliminating the need for secondary finishing.

We utilize state-of-the-art CNC-controlled water jet systems to achieve precise cutting tolerances, making it ideal for intricate designs, complex shapes, and high-precision components. Whether for aerospace parts, medical instruments, or custom industrial applications, our cutting-edge technology ensures superior quality and accuracy.

Environmental sustainability is a key advantage of water jet cutting. This process generates minimal waste, reduces material usage, and eliminates harmful fumes or chemicals, making it an eco-friendly alternative to traditional machining methods. Additionally, it allows for efficient material utilization, leading to cost-effective manufacturing solutions.

From prototyping to large-scale production, our water jet cutting capabilities provide manufacturers with a reliable and efficient solution for precision cutting. By combining innovation with advanced engineering, we help industries achieve superior performance, durability, and design flexibility in their manufacturing processes.

Laser Cutting & Robotic Welding

Laser Cutting & Robotic Welding Solutions

Modern manufacturing demands precision, efficiency, and automation, and laser cutting and robotic welding play a vital role in achieving these goals. These advanced technologies are widely used in industries such as aerospace, automotive, medical, and industrial fabrication, ensuring high-quality production with minimal waste and maximum accuracy.

Laser Cutting: Precision & Versatility

Laser cutting is a highly precise and efficient method for cutting a variety of materials, including stainless steel, aluminum, titanium, and composites. Using high-powered lasers controlled by CNC systems, this process delivers clean, burr-free cuts with minimal heat-affected zones (HAZ), preserving material integrity and reducing the need for post-processing.

Our laser cutting solutions offer: ✔️ High-Speed & High-Precision Cutting – Perfect for intricate designs and complex geometries. ✔️ Non-Contact Process – Reduces material deformation and enhances durability. ✔️ Versatility in Materials – Works with metals, plastics, and composites. ✔️ Cost-Effective Production – Minimal material waste and optimized efficiency. From aerospace components to custom automotive parts, laser cutting enables fast, accurate, and scalable manufacturing with tight tolerances and superior quality. Environmental sustainability is a key advantage of water jet cutting. This process generates minimal waste, reduces material usage, and eliminates harmful fumes or chemicals, making it an eco-friendly alternative to traditional machining methods. Additionally, it allows for efficient material utilization, leading to cost-effective manufacturing solutions.

Robotic Welding: Strength & Consistency

Robotic welding is a fully automated process that ensures strong, consistent, and high-quality welds across various applications. It eliminates human error, increases production speed, and enhances structural integrity in critical components. Our robotic welding solutions provide: ✔️ Unmatched Precision & Repeatability – Ensures consistent welds across large production runs. ✔️ Stronger & More Durable Joints – Improves structural integrity for aerospace, automotive, and heavy industries. ✔️ Enhanced Safety & Efficiency – Reduces manual labor risks and increases production speed. ✔️ Seamless Integration with Automation – Works with CAD/CAM systems for optimized workflow. By utilizing robotic welding, we ensure high-strength, defect-free joints in assemblies, making it ideal for applications requiring extreme durability, such as aircraft structures, automotive chassis, and industrial equipment.

Advancing Manufacturing with Smart Automation

By integrating laser cutting and robotic welding, we offer turnkey manufacturing solutions that combine speed, precision, and cost-effectiveness. These advanced technologies drive innovation, ensuring high-quality, scalable production while reducing downtime and operational costs. From prototyping to mass production, our expertise in laser cutting and robotic welding provides the reliability, accuracy, and efficiency that modern industries require.